Applications

Latest News

- >New Product: Tuning Fork Liquid Level Switch with Stainless Steel Housing

- >New Product:Vibrating Rod Level Switch With Suspension Cable

- >SIL Certifications with CNCA Authority

- >Export Growth Sharply in the First Half of 2023

- >Hastelloy Tuning Fork Liquid Level Switch Newly Launched

- >Extra-Long Vibrating Rod Level Switches Applied to Precipitates Interface Measurement of Liquids

- >New Ultrasonic Product: Anti-interference Ultrasonic Level Transducer

- >Vibrating Rod Level Switch:Ideal Solution for Level Detection of Viscous Powder

Contact Us

Shenzhen Jiwei Automations Ltd.

Address:5th Floor, Baoli Building, No. 3162 Longgang Avenue, Shenzhen, P. R. China.

Tel:+86 755 28407683

Other Industries

- Location:

- Home

- >

- Applications

- >

- Other Industries

Signal Outputs Selection of Tuning Fork Liquid Level Switch for Highly Dynamic Fluid Levels

In practical applications, some of the rapidly changing fluid levels in small containers or pipelines can result in overflow. In the small-volume containers and pipes, the fast liquid flow rate is a potential problem of danger. A proper signal output selection of the liquid level switch can avoid or solve the problem.

Tuning Fork Liquid Level Switch comprises a two fork tines which is driven by a piezo-crystal assembly to oscillate at its natural frequency. The fork sensors are typically factory calibrated and set at a specific frequency depending on the type of industry. When in air, the forks vibrate at their natural frequency; when liquids cover the forks, the frequency of oscillation drops and is detected by the integrated circuit, which in turn changes the output state.

Compared with other level detection instruments, Tuning Fork Liquid Level Switch has strong anti-interference ability and it is not easily affected by foam and bubbles. At the same time, most viscous liquids are also able to be measured. With high reliability, the accuracy error of Jiwei Ring-11 Tuning Fork Liquid Level Switch is within ± 1mm. Ring-11 has passed SIL2/3 safety certification, intrinsic safety and explosion-proof certifications. The forks are only 40mm long, and the minimum measurable liquid density reaches 0.5g/cm ³, suitable for liquid level measurement in small containers or pipelines.

There are four signal outputs (relay, two-wire, NAMUR, and transistor) that can be chosen from Ring-11 Tuning Fork Liquid Level Switch.

1. Relay (DPDT): The power supply adopts AC/DC, with a power supply range of 20~253V AC/20~72V DC. It is intelligently identified and matched by internal circuits, and the signal output can be freely selected as normally closed or normally open. This is a commonly used output, which can directly control multiple instruments and with a wide range of applications.

2. Two-wire: DC power supply is adopted for range 10~36VDC, with alarm output 8mA or 16mA. With the intrinsic safety certification and the small output current value, designed for safety performance occasions.

3. NAMUR: it only needs to provide a DC voltage of about 8V. The alarm signal outputs a current signal of ≤ 1mA or ≥ 2.1mA, which is lower in current and voltage compared to a two-wire system of 8mA/16mA. NAMUR signal outputs are all intrinsically-safe instruments, usually can be combined with isolated safety barriers in hazardous environments.

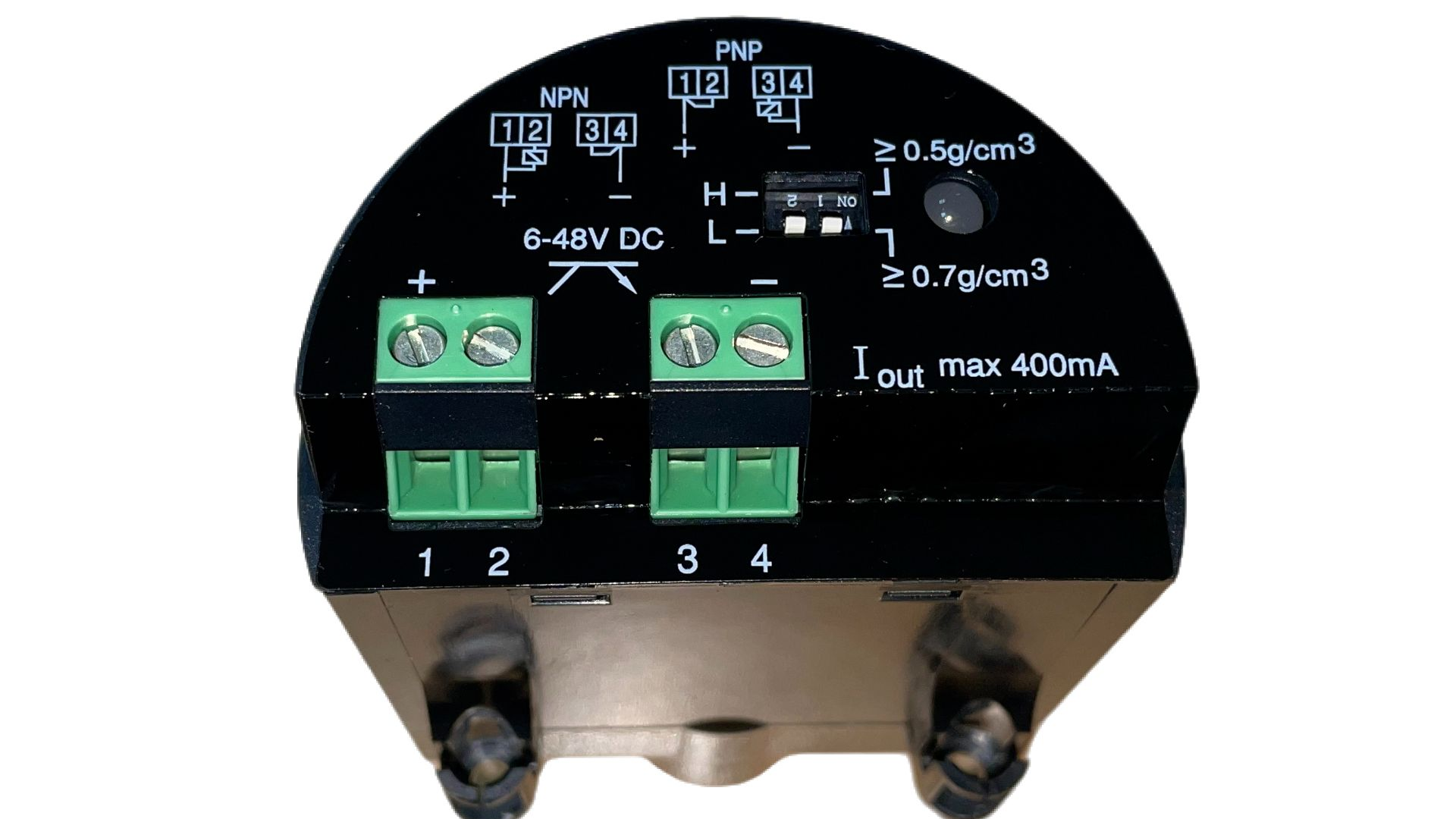

4. Transistor: 6~48V DC power supply is adopted, PNP or NPN output mode can be selected. Due to the low output drive current, high response frequency, and durable life of, the transistor is suitable to control servo controllers, solid-state relays, and other applications with high frequency operations and requiring long service life.

Among the above four signal outputs, two wire and NAMUR are both low current outputs, which are commonly used in hazardous environments; relay and transistor are generally used in a wider range of applications. Generally, relay and transistor can directly control starting devices, providing faster response than two-wire and NAMUR output modes, and are suitable for situations where rapid response is required to prevent overflow. Relay belongs to mechanical components, the response time is slower than that of transistor. In addition, the relay has limited mechanical life and switching times per minute, proper for occasions in low action frequency. Transistors are electronic components with longer service life, and are particularly for high switching frequency applications.

Therefore, Transistor offers a very rapid response time, enabling measurement of rapidly changing fluid levels or sloshing liquids, and more effectively preventing the occurrence of overflow accidents.

Previous:Anti-Adhesive Coating for Tuning Fork Liquid Level Switches

Previous:Anti-Adhesive Coating for Tuning Fork Liquid Level Switches Next:Analysis of the Advantages and Disadvantages of Double Rods and Single Rod Vibrating Rod Level Switch

Next:Analysis of the Advantages and Disadvantages of Double Rods and Single Rod Vibrating Rod Level Switch